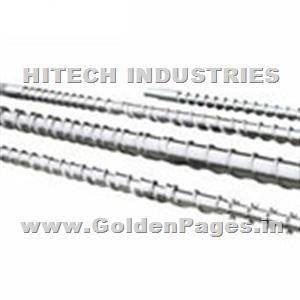

Extrusion Single Screw And Barrel

HI-TECH EXTRUSION is one of the most leading and reputed manufacturer of the extrusion screws and barrel with designs of all the reputed extrusion machine manufacturer.

Designs are available for single flight metering screws, single barrier screws, double barrier screws, variable pitch flights, multi start flights and slotted flights.

Mixing sections, the more common of which, include Maddock (spiral or straight), Hoechst, dulmage, pinned, pineapple or combinations of these designs are available. Our varieties of screws ranges from 18mm up to 200mm depending on L/D ratio.

Specification :-

Diameter : Φ18-Φ200mm

L/D=15-56

Length of screw and cylinder: UP TO 6000mm

Clients can avail from us the best quality twin screw- barrels for extrusion. These barrels are bimetallic and tungsten coated for wear protection and is widely used in plastic machines like injection moulding machine or extruders. Client can avail this product at the most affordable price according to the diameter, length-diameter ratio and quality raw material to provide high performance.